Food Processing, Cookware & Bakeware

Food Processing, Cookware & Bakeware Coating Services

The food processing, cookware and bakeware industry requires durable, long-lasting FDA compliant coatings that offer repeatable release of food products and can withstand high cooking and baking temperatures.

Orion is a Licensed Industrial Applicator (LIA) of Teflon™ coatings, including non-stick PTFE, PFA, ETFE and Teflon™-S FEP, as well as PPG/Whitford Xylan® coatings and many other FDA compliant food processing, cookware and bakeware coatings.

We have 60 years of experience applying functional coatings designed for food contact – from commercial food processing equipment to consumer cookware and bakeware. We use automated, robotic equipment to ensure precise, uniform and consistent high-quality application of coatings.

All of the food processing coatings we apply comply with FDA regulations in 21 CFR governing components of coatings for direct food contact when applied according to manufactures' instructions. We can make any coating anti-microbial upon request.

Contact us today to speak with a technical consultant about your food processing, cookware or bakeware coating project.

Teflon™ is a registered trademark of Chemours and is used under license by Orion Industries, Ltd.

Application Examples

- Commercial bakery

- Baking pans

- Die cast products

- Glass bakeware

- Glass lightbulbs

- Broiler pans

- Burner bowls

- Cheese, chocolate and other molds

- Chicken rotisseries

- Chutes

- Conveyer system components

- Cookware/frying pans

- Dough bowls and troughs

- Egg rings

- Griddles

- Heat sealing bars

- Roller grills

- Mixing and cutting blades

- Pizza pans

- Proofing trays

- Sheet pans

- Utensils

- Waffle grids

- Wire products

Commercial waffle grids/irons on curing oven conveyor

Hot dog roller grill

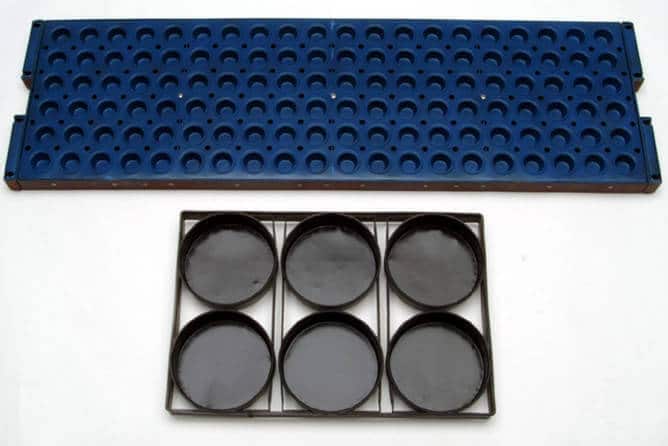

Teflon™ Non-stick coated bakeware

Teflon™ Non-stick coated bakeware

Teflon™ Non-Stick coated waffle grid/iron

Teflon™ Non-stick coated commercial bakeware

Commercial Food Processing Equipment Coating Refurbishment Service

Orion's Refurbishment Services for the non-stick release of high-volume cooking and baking surfaces for commercial food processing lines provides renewed non-stick surface service life. Each type of cooking or baking device has somewhat different end-use requirements. We provide a restored surface to provide long-term performance of our non-stick coatings for food processing, including premium non-stick, FDA approved, food contact coating materials, such as application of Teflon™ PTFE coatings.

Our Teflon™ coating services and refurbishment starts with a careful removal of all food products and the entire original nonstick coating (fig. 1 - part as received). The result is a precisely textured and cleaned surface, providing a foundation to restore the non-stick properties.

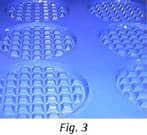

Orion has perfected the coating removal process with automated machinery that creates the optimum clean, textured metal surface. We prevent over-roughening of the substrate due to excessive grit blasting. This closely controlled procedure maintains the substrate and maximizes the production life of your asset (fig. 2 - cleaned and retextured). We then apply a premium grade non-stick coating materials to restore the non-stick properties (fig. 3 - first base coat).

The result is a restoration process that maintains the life of our customers' food processing equipment as long as possible. Our surface renewal process and PTFE application provides consistent and predictable service life.

Reliable and consistent turnaround of restored commercial surfaces is a primary focus at Orion Industries. In the 60 years we have provided non-stick PTFE coatings for food processing equipment, we have invested and developed optimized equipment to effectively remove and restore product surfaces (see image of completely refurbished waffle mold).

We can process hundreds of production line components per day and have an extensive arsenal of cleaning and coating equipment with multi-shift production teams. We provide the shortest turnaround cycle possible to keep your operation flowing smoothly. We stock an extensive inventory of fluoropolymer and silicone coating materials to provide a reliable and consistent refurbishment and recoating service.

Click here to read a Calphalon Food Industry Success Story

Click here to read a Morning Delight Food Industry Success Story

Click here to read a Vollrath Food Industry Success Story

Click here to read a Spanek Food Industry Success Story

Click here to read a West Bend Food Industry Success Story

Teflon™ is a registered trademark of Chemours and is used under license by Orion Industries, Ltd.