Aerospace & Defense

Aerospace & Defense Coating Services

Aerospace and defense coatings are designed to protect mission critical aerospace and military assets from harsh operating conditions and environments such as extreme temperature variations, corrosion, and abrasion.

As an AS9100D and ISO 9001:2015 certified, and ITAR registered company, Orion's aerospace and defense coating services adhere to strict application processes and materials. We have coated a wide range of aerospace and defense components, following defined specifications for Military (MilSpecs), Aerospace and Industrial applications.

Key Facts About Aerospace & Defense Coatings

A variety of high-performance coatings are used on aerospace and defense components, including Teflon™, Molybdenum disulfide, Halar®, Xylan®, FEP, PFA, and Nylon.

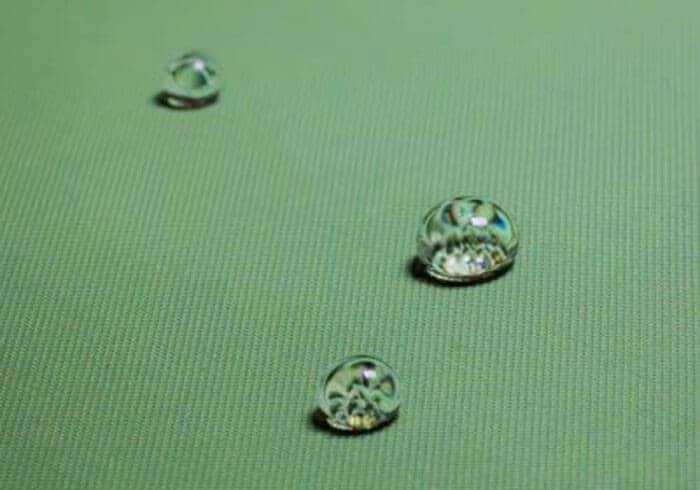

Teflon™ PTFE coatings are widely used in aerospace and defense due to their ability to withstand extreme temperatures - up to 260°C (500°F) and as low as -270°C (-450°F) - without losing key performance traits like lubricity, abrasion resistance, or structural integrity. These characteristics make PTFE ideal for high-demand aerospace environments, from cryogenic fuel systems to components exposed to high thermal stress.

Teflon also offers strong chemical resistance, making it especially well-suited for cryogenic and corrosive environments. In aerospace and military applications, PTFE coatings help protect components exposed to heat, wear, and corrosion, enabling long-term storage of equipment without routine maintenance.

While other fluoropolymers like FEP and PFA perform well at extreme temperatures, PTFE supports a broader operational range. This makes it a preferred material not only for defense applications but also for space exploration. PTFE-coated components are used on mechanical land rovers on both lunar and Martian surfaces.

In commercial aerospace, Teflon coatings are commonly applied to fasteners, bearings, fuel system components, engine parts, and even cabin hardware such as toilets and clamps. These coatings meet stringent industry standards like BMS10-146 and AMS2512.

Molybdenum disulfide (moly) coatings offer a different set of advantages. Though not as low-friction as PTFE, moly coatings excel in high-load environments where oil and grease may be displaced or contaminated. With heat resistance up to 426°C (800°F), moly coatings function as dry lubricants in high-friction, high-pressure applications.

Together, these technologies form the foundation of advanced aerospace and defense coatings, serving everything from rocket propulsion systems to mission-critical components.

The Orion Industries Difference

You can count on Orion’s 60 years of innovation and advanced technologies for precise, repeatable, high-quality application of coatings. As one of the leading aerospace coating applicators, we are the most automated, high-precision applicator in North America.

Our expertise spans a wide range of aerospace components - from PTFE-coated titanium blades used in jet engines to helicopter parts that require anti-vibration coatings to prevent galling and fretting.

We are REACH and RoHS compliant and proudly serve the commercial, space, and defense sectors. As an experienced MilSpec coating applicator, we hold ITAR registration and meet military specifications for PTFE, moly and other coatings.

Orion applies high-load moly coatings capable of withstanding over 100,000 psi, frequently used in sophisticated ammunition, firearm shields, bushings, thrust washers, and bearing retainers.

With a focus on precision and automation, we are able to consistently hold coating tolerances as tight as ±3 microns - the average diameter of a human hair is 100 microns - on components as small as a 0.375-inch diameter shaft over a 12-inch length in high-volume production.

We are a cell-oriented coatings applicator and build our own equipment to handle the high-volume, repeat order demands of our customers. This level of precision and capacity means you can expect quality, consistency, repeatability and on-time delivery - whether for a few hundred parts or over a million.

As a leader in high-performance functional coatings and their application, Orion remains committed to pushing the boundaries of what's possible in aerospace and defense coatings.

Contact us today to speak with a technical consultant about your aerospace and defense coating project.

Teflon™ is a registered trademark of Chemours and is used under license by Orion Industries, Ltd.

Application Examples

- Ammunition components

- Bearing retainers

- Bushings

- Clamps, clips & connectors

- Defense/Military components

- Fasteners

- Filter housings

- Filtration media/cloth/screen

- Firearm shields

- O-rings, gaskets & seals, including k-seals & NAFLEX seals

- Rocket components

- Rotors

- Struts, strut supports & strut mounts

- Thrust washers

- Titanium curved blades

- Toilet bowl components

PTFE Coatings for Aerospace Component

PTFE Coated Filtration Media

Industrial PTFE Coating for EVAC Aerospace Components