Production Equipment

Automated, High-Tech Equipment and Processes

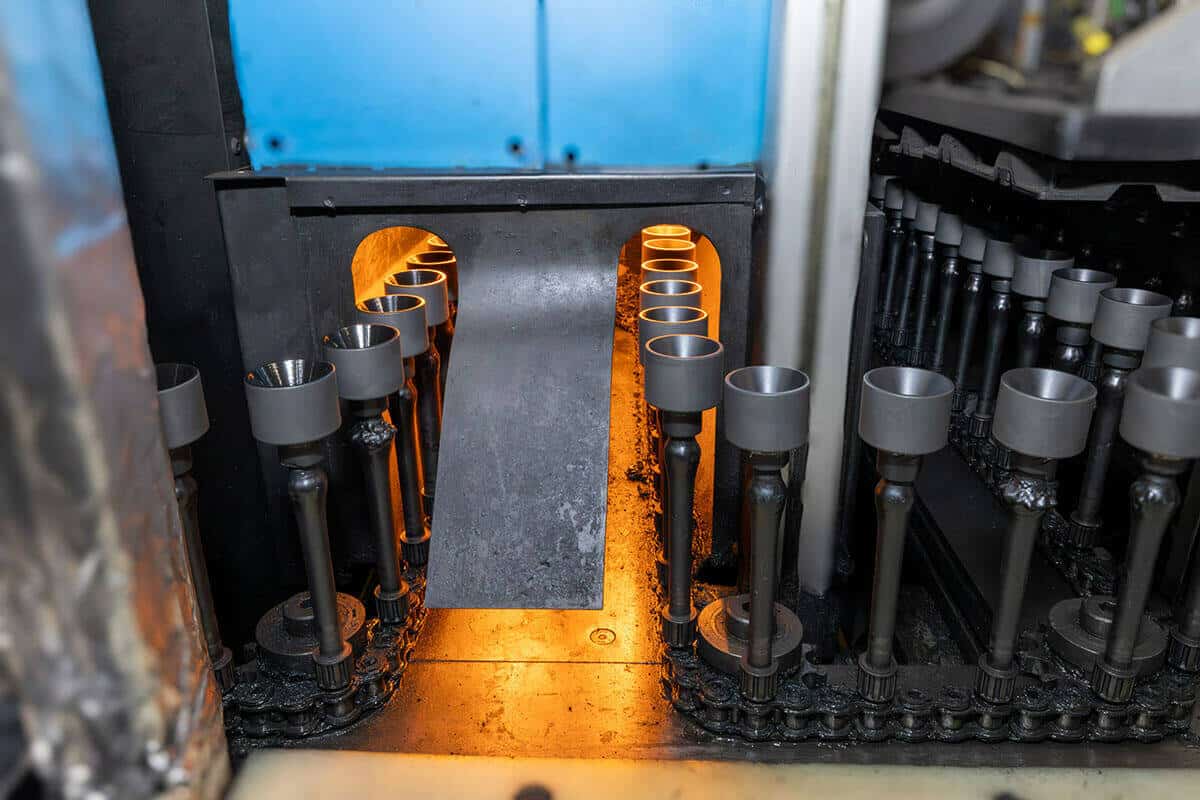

Precise, automated application of functional coatings is the foundation of our consistent quality and delivery. Production machinery, tooling and fixtures are built in-house, enabling jobs to begin in weeks rather than months.

Precise, automated application of functional coatings is the foundation of our consistent quality and delivery. Production machinery, tooling and fixtures are built in-house, enabling jobs to begin in weeks rather than months.

Our production lines are expandable by duplicating fixtures and running on parallel lines. Production consistency is maintained regardless of shift changes or the longevity of each project.

Our entire production process is based on a computerized bar-code scanning system, which accounts for time, materials, and product flow through various operational sequences. We employ 100+ quality control tools for quality assurance.

Custom Engineered Solutions

Our in-house machine shop and fabrication facility enables our engineers to build everything from fixtures, ovens, racks and carts, to several automated spray/oven and computer-controlled production lines. Our staff includes engineers and technicians familiar with all machinery in order to maximize production up time. After setting up machines, operators are involved in the continuous testing and checking of coating attributes as our equipment provides consistent and precision coating application.

Orion staff builds the most precise and efficient robotic equipment to apply coatings in-house, ensuring you receive high-quality and cost-effective application in production. Orion is proud to house a well-equipped and diverse functional coating production facility.

Prototyping, Short-run and Long-run Production

Orion Industries has small batch ovens for prototyping or short-run production order processing, flat belt conveyor ovens for high-volume production processing, and overhead conveyor lines that can process a multitude of different parts in short-run or high-volume production. Our flexible cell operations include medium to large batch ovens up to hold parts up to 6.5 feet x 7 feet x 10.5 feet long. More automation capacity includes eleven medium to heavy-duty, chain-on-edge production lines with large conveyor ovens. All of our ovens are built to process coatings at temperatures up to 850ºF.

Pretreatment Services

Our pretreatment lines include automatic and manual grit blasting operations along with large tumble grit blasting machines and medium tumble blasters and wheel abraders. Phosphating and anodizing services are available from ISO certified suppliers located minutes from Orion. Our flexible cell equipment inventory includes numerous automatic and semi-automatic coating application machines to apply accurately controlled coatings.

Contact us to speak with a technical consultant about your specific project's production requirements.